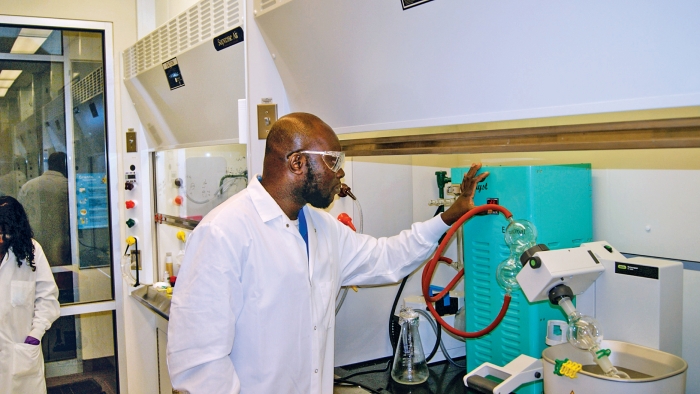

Lab Rotary Evaporators for Cannabis & Hemp

Rotary evaporators are adopted in the specialized collection of various forms of evaporated matter. Industries that would benefit from the extraction of evaporated oil, liquid, or gas utilize rotary evaporator equipment of varying capacity and size to retrieve valuable materials and substances.

At Ecodyst, we specialize in the groundbreaking rotary evaporator systems, manufacturing models that come in a huge spectrum of sizes, capacities and with supreme capabilities.

The Benefits of Ecodyst Rotary Evaporators

Cost-Effectiveness

The financial benefit of opting for Ecodyst’s high-spec rotary evaporators is two-fold.

In the short term, the initial purchase cost is similar to the models of our closest industry competitors. The fact that we can offer a far more expedient, straightforward extraction method for a comparative cost is testament to our designers and engineers. Cannabis and hemp extractions has traditionally been an expensive process but with our money and resource-saving approach, the industry has become accessible.

In the long-term, customer feedback has supported our claims of superior construction and quality. The relatively low rate of instances when our rotary evaporators have required maintenance is evidence of this. With no secret costs or concealed operation fees further down the line, clients can rest assured that they have chosen the best option on the market without paying over the odds.

Time-saving Technology

Having done away with all of the big, heavy equipment – tanks, tubes, and so on – that were an essential aspect of past evaporation experiments, we have massively reduced the time needed for setup and procedure. Previously, cannabis and hemp extraction has proved to be a painstaking and detailed undertaking, but Ecodyst’s efficient equipment has made the process more profitable.

Our proprietary direct self-cooling systems drastically reduce the excess time previously wasted on freezer-based cooling methods.

Unique Usability

With one eye on evolution and modernization, Ecodyst’s team of experts has tirelessly and continuously come up with clever controls and functions. More accurate temperature control and alternative extraction techniques are just two of the significant modifications that have made our rotary evaporator equipment systematically superior.

Ecodyst Rotary Evaporator Models for Cannabis & Hemp Production

Decarboxylation (decarbing) is globally renowned as the most reliable and effective way to extract the highest substance samples with the greatest potency.

Ecodyst is the proud producer of some of the world’s most advanced rotary evaporators applied to the decarbing of cannabis on a wide scale. Our EcoChyll® range of evaporators, with its direct cooling systems and continuous vacuum, feeds ticks all the boxes for researchers desperately seeking a comprehensive extraction tool.

Ecodyst offers rotary evaporators for jobs of any size or substance with systems carrying colossal capacities of 200L (EcoChyll® X9) to the more modest 12L (EcoChyll® X3) evaporators.

To hear about our unrivalled brand range or to ask about particular specifications, contact us today and we’ll be happy to deal with any and all enquiries.